Choosing CO2 Cartridges That Protect Airgun Mechanisms

To protect an airgun’s valve, piercing seal, and internal O-rings, choose CO₂ cartridges that are filled with controlled purity, low moisture, and minimal hydrocarbon/oil carryover then verify consistency through leak testing and batch traceability. In practice, “bad CO₂” damage is usually caused by contamination, unstable pressure delivery, or poor sealing/neck geometry that accelerates wear and leakage.

What this means and why it matters

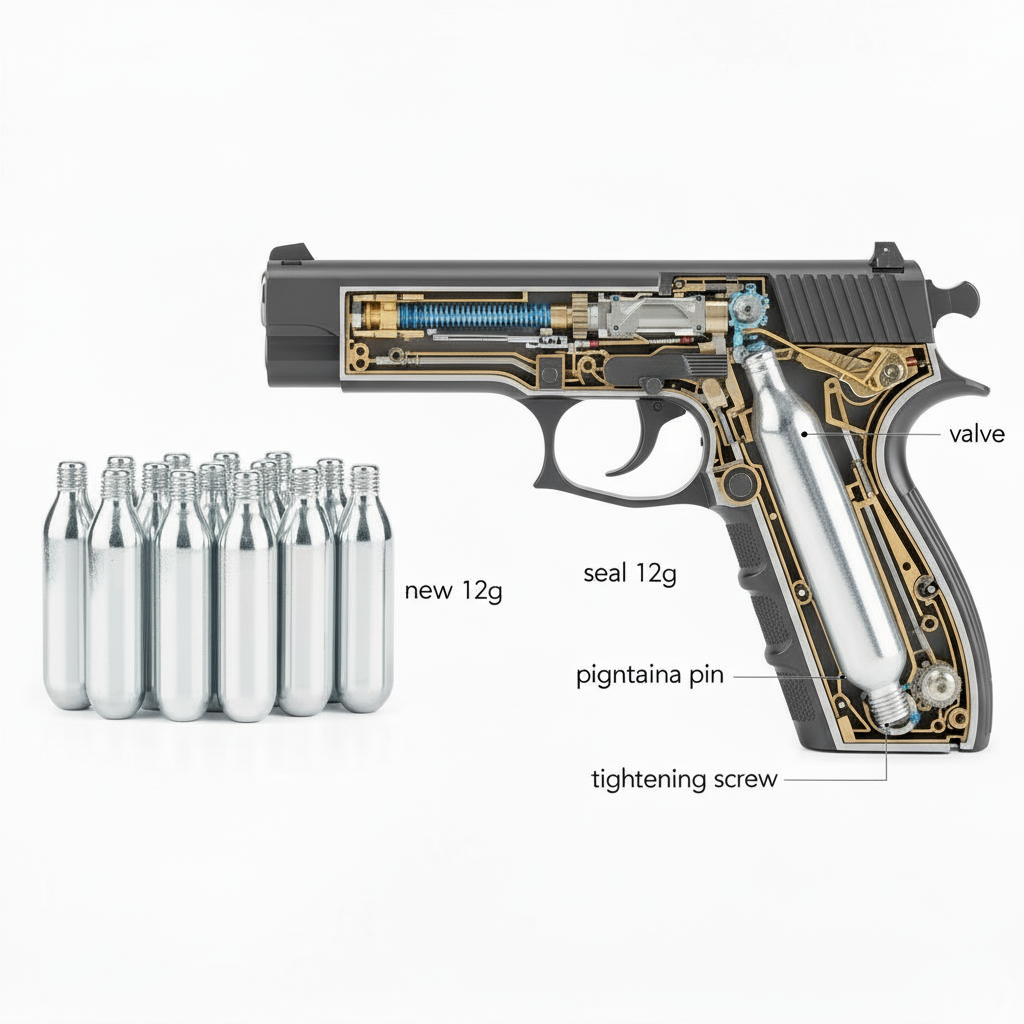

A CO₂ cartridge is not only a gas container—it is a pressure source that drives a metering valve system. When cartridge gas quality is inconsistent (moisture, oil residue, particulates) or when the cartridge sealing surfaces vary (neck finish, piercing point, gasket contact area), the airgun’s soft components take the stress: seals harden, swell, or cut; valves stick; and velocity consistency drops.

For airgun brands, retailers, and high-volume users, cartridge quality directly affects:

- Leak rate (piercing seal + valve seat condition)

- Shot-to-shot consistency (pressure stability + flow repeatability)

- Component life (O-ring compatibility + corrosion control)

- Warranty/returns (customer complaints often trace to gas supply quality, not the gun)

Populargas manufactures CO₂ cartridges for global supply (OEM/ODM). See product categories here: https://www.populargas.com/product/ and company capability overview here: https://www.populargas.com/about/.

How low-quality CO2 harms airgun mechanisms

Seal degradation and leakage

Airguns rely on elastomers (commonly NBR/HNBR/urethane depending on design). Problems typically show up as:

- Piercing seal leaks immediately after installation

- Slow leaks over hours/days due to surface imperfections or chemical attack

- Seal extrusion/cutting from poor neck geometry or sharp edges

Root causes include moisture, hydrocarbon residues, incompatible additives, and inconsistent cartridge mouth finish.

Valve sticking and inconsistent output

Contaminants can deposit on valve seats and transfer passages. The result is:

- Valve stick-slip (delayed opening/closing)

- Power loss (restricted flow)

- Velocity spread (unstable gas delivery)

Corrosion and internal wear

Moisture is a long-term reliability issue. Even small water content can accelerate:

- Corrosion in metal components

- O-ring hardening

- Surface pitting that worsens sealing over time

What to check when selecting CO2 cartridges for airguns

Gas quality controls (what matters in practice)

Look for evidence of:

- High CO₂ purity (supplier-controlled, consistent batches)

- Low moisture content (reduces corrosion and seal damage)

- Low hydrocarbon/oil carryover (reduces elastomer swelling and valve deposits)

- Filtration and clean filling practices (reduces particulates)

Cartridge integrity and sealing geometry

A mechanically correct cartridge protects the gun even before gas quality is considered:

- Consistent neck dimensions and mouth finish

- Reliable piercing behavior (no burrs, no excessive deformation)

- Verified leak tightness (mass/pressure leak testing)

Documentation and traceability

For B2B supply (retail, distribution, OEM/ODM), require:

- SDS (Safety Data Sheet) for the CO₂ package

- Batch/lot traceability

- Test records aligned with your market requirements (transport labeling, Class 2.2 where applicable)

Comparison table: “Good” vs “risk” cartridges for airgun protection

| Control point | Good cartridge behavior | Risk pattern you see in the field | Typical airgun symptom |

|---|---|---|---|

| Moisture control | Low moisture, stable storage behavior | Moisture present / variable | Corrosion, seal hardening, slow leaks |

| Hydrocarbon carryover | Minimal oil/residue | Residue from filling/lubricants | O-ring swelling, valve sticking |

| Particulate control | Clean fill + filtration | Fine debris/particles | Seat damage, inconsistent velocity |

| Neck/mouth finish | Consistent, smooth sealing surface | Burrs, rough finish, variation | Piercing seal leaks, cut seals |

| Leak testing | Verified tightness per lot | No consistent verification | Early returns, “empty overnight” complaints |

| Traceability | Lot ID + documentation | No lot control | Hard to root-cause failures |

Comparison table: common CO2 cartridge sizes used around airguns

| Size | Typical use context | Notes for mechanism protection |

|---|---|---|

| 8g | Compact devices / specialty applications | Small volume; consistency depends heavily on fill control |

| 12g | Most common airgun size | Most returns occur here due to high volume—tight process control matters |

| 16g / 24g | Some airgun and accessory systems | Verify compatibility with the specific airgun adapter/valve design |

| 38g | Larger accessories and certain systems | Ensure consistent sealing interface and leak testing |

| 88g | Bulk CO₂ for some rifles/adapters | Longer run time increases importance of moisture control and valve cleanliness |

Real application examples across industries

Airgun distribution and retail

Retailers often maintain safety files and handle customer returns. Inconsistent cartridges create a pattern: “gun leaks” complaints that disappear when cartridges change. The fix is not guesswork it is supply control: moisture/contaminant limits, stable neck finish, and lot traceability.

Beverage systems and cold-room storage

Beverage CO₂ systems run in enclosed or cold environments where pressure stability and documentation matter. Clean filling and consistent CO₂ supply reduce operational issues, while SDS and labeling support compliance and safe handling.

Marine safety inflation devices

Inflation systems require reliable activation under time pressure. Cartridge geometry and sealing integrity matter as much as gas quality, because failure modes are often mechanical (leak paths, piercing behavior).

Food processing audits

Food facilities care about documentation, handling procedures, and predictable equipment performance. A controlled CO₂ package supports audit readiness through consistent supply and traceable lots.

Industrial gas systems and EHS controls

In industrial environments, CO₂ is managed under EHS procedures (ventilation, confined-space risk awareness, transport compliance). A complete documentation set and stable cylinder quality reduce safety and logistics disruptions.

FAQ

Does CO2 purity matter for airguns?

Yes. Purity alone is not the only factor, but higher, controlled purity reduces the likelihood of contaminants that contribute to seal swelling, valve deposits, and inconsistent output.

Why do some CO2 cartridges cause airguns to leak?

Leaks are commonly caused by variation in the cartridge sealing surface (mouth/neck finish), poor piercing behavior, or contaminant-driven seal degradation. Consistent geometry plus leak testing reduces this risk.

Can moisture in CO2 damage an airgun?

Yes. Moisture increases corrosion risk and can accelerate seal hardening and wear, especially during storage or in cold environments.

What is the most common CO2 cartridge size for airguns?

12g is the most common for many air pistols and CO₂-powered platforms, while 88g is used in some rifles and bulk-adapter systems. Always match the cartridge size to the airgun’s design and adapter specification.