Learn about the different types of welding gases

The Different Types of Welding Gases and Their Uses

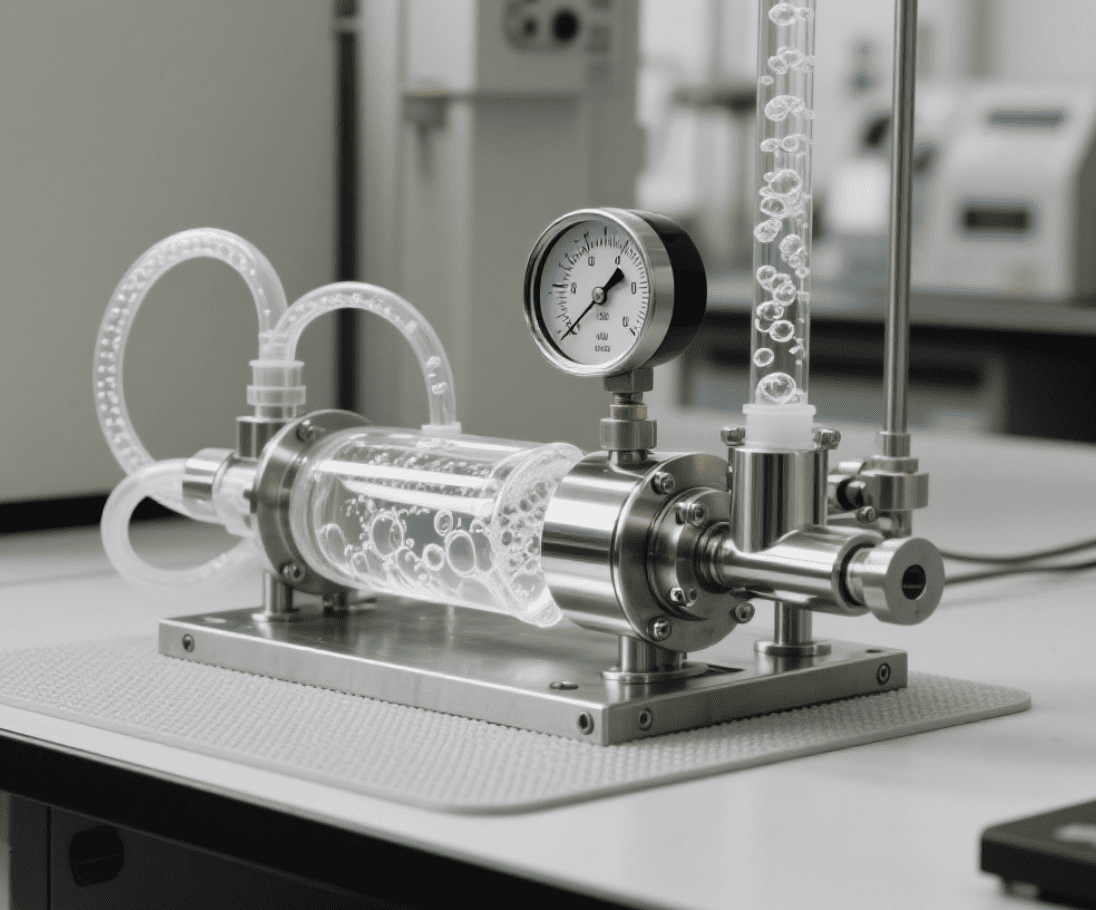

Welding is a precise craft that requires the right equipment and materials to achieve strong, durable, and clean welds. One of the most important elements of the welding process is the selection of welding gases. Welding gases help control the heat, protect the weld pool, and ensure high-quality finishes. Choosing the right gas for your project can significantly impact your results, whether you are working on a small metal fabrication or large industrial structures.

What Are Welding Gases?

Welding gases are used in various welding processes to enhance the quality and precision of the weld. These gases protect the molten metal from contamination by shielding it from oxygen and other atmospheric elements that can weaken the weld. Different gases are used for different welding techniques, and understanding their properties can help improve your welds and the efficiency of the welding process.

The most common welding gases include argon, oxygen, carbon dioxide (CO2), acetylene, and helium. Each gas serves a specific function and is best suited for particular materials and types of welding.

Types of Welding Gases

Argon

Argon is one of the most commonly used gases in welding, especially for Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding. Argon is an inert gas, meaning it does not react with the material being welded, creating a clean and stable arc. It is ideal for welding non-ferrous metals like aluminum and stainless steel, providing excellent control over the heat input.

Advantages:

Produces high-quality, clean welds with minimal spatter.

Ideal for thin and delicate materials.

Works well with a variety of materials, especially non-ferrous metals.

Oxygen

Oxygen is often used in combination with other gases, such as acetylene, in oxy-fuel welding and cutting. When mixed with acetylene, oxygen generates an extremely high-temperature flame that can easily melt metals, allowing for cutting or welding,such as the xxx(embedded link)

Advantages:

Increases the temperature of the flame, making it useful for cutting and welding thicker materials.

Provides precise control over the flame.

Essential for certain welding processes, like oxy-acetylene welding.

Carbon Dioxide (CO2)

CO2 is widely used in MIG welding, particularly when welding thicker materials. While CO2 is not inert, it is effective in shielding the weld pool from contamination. It is an economical choice because it’s less expensive than other gases like argon and helium,such as the Populargas.

Advantages:

Strong arc penetration and deep welds.

Ideal for welding ferrous metals, such as steel and iron.

Cost-effective, making it popular for high-volume welding jobs.

Acetylene

Acetylene is commonly used in oxy-acetylene welding, a process where acetylene is mixed with oxygen to create a hot, controlled flame. Acetylene produces a high-temperature flame, making it ideal for welding, cutting, and brazing applications.

Advantages:

Generates a high-temperature flame, which is excellent for welding and cutting thick materials.

Used in a variety of applications, from metal fabrication to repair work.

Helium

Helium is another inert gas, typically used in TIG welding. It is often mixed with argon to provide a more stable arc and higher heat input. Helium is ideal for welding thick materials like stainless steel and aluminum.

Advantages:

Increases heat input and improves weld penetration.

Provides better control over the welding process.

Excellent for high-heat welding applications.

Choosing the Right Welding Gas

Selecting the right welding gas is essential for achieving optimal welds. When choosing a gas, consider the following factors:

Material: Different materials require different gases. For example, aluminum and stainless steel benefit from argon or helium, while CO2 works well with ferrous metals.

Welding Process: The type of welding process (TIG, MIG, oxy-acetylene, etc.) will determine which gas is best suited for your project.

Budget: Some gases, like argon and helium, are more expensive than CO2, so budget constraints may influence your choice.

It’s also worth considering gas mixtures. Sometimes, a blend of gases (e.g., argon and CO2) is used to balance cost and performance, particularly for MIG welding.

Common FAQs About Welding Gases

Q1: Which gas should I use for stainless steel?

For stainless steel, argon is the most commonly used gas, often mixed with small amounts of CO2 or helium to improve penetration and heat input.

Q2: How do I know if I need a gas mixture?

Gas mixtures are often used to balance cost and performance. For instance, combining argon with CO2 can increase weld penetration while reducing costs. If you are welding thick metals or need high heat input, a mixture may be beneficial.

Q3: Can welding gases be reused or recycled?

While the gas itself can’t be reused, the cylinders and equipment used to store and deliver welding gases can be recycled. Always follow your local regulations for proper disposal.

Conclusion

Choosing the right welding gas is crucial for achieving strong, clean, and precise welds. Whether you’re working with delicate metals or large industrial projects, understanding the properties of different welding gases and their applications can help improve the quality of your work. Make sure to choose the gas that best suits your project’s needs, and you’ll see a noticeable difference in the results.

Do you want to know more about welding gas cylinders?The PopularGas is a good example.

Innovative Features of Modern

Innovative Features of Modern

The Science Behind Carbonated

The Science Behind Carbonated

How to Care for Carbonated Sod

How to Care for Carbonated Sod

The Evolution of Carbonated So

The Evolution of Carbonated So