How to Care for Carbonated Soda Machines

Introduction — Why Soda Machine Maintenance Matters

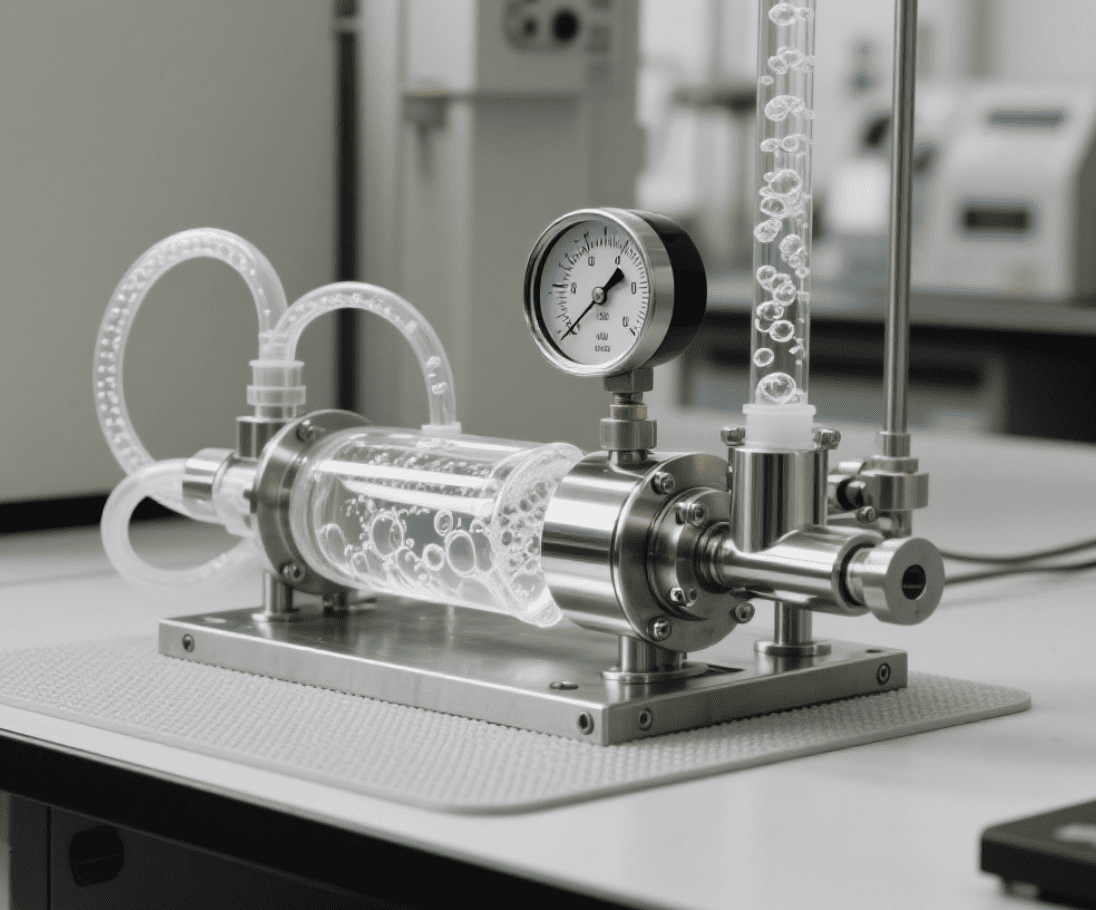

A carbonated soda machine offers a refreshing way to enjoy fizzy drinks at home or in a commercial setting. But to keep that satisfying fizz going strong, regular maintenance is essential. Over time, residue buildup, CO2 inefficiency, or poor hygiene can impact both the taste and performance of your soda system. Whether you own a home soda maker or manage a commercial soda dispenser, proper care ensures your machine stays clean, efficient, and safe to use.

Daily and Weekly Cleaning Routines

Establishing simple cleaning routines prevents major issues down the line. For both home and commercial machines:

Wipe the nozzles and exterior surfaces after each use using a damp cloth. This helps prevent stickiness from flavored syrups or water splashes.

Rinse reusable bottles and caps thoroughly with warm water to avoid bacterial buildup.

Clean the syrup chamber or flavor cartridge area weekly if your model includes one.

For systems that dispense multiple flavors, cross-contamination can occur. Use soft brushes to reach narrow areas, and avoid using abrasive materials that may damage the machine’s surface.

Monthly Deep Cleaning & Descaling

Even if daily cleaning is performed, a monthly deep clean is necessary to maintain internal hygiene and system performance.

Descale the internal water lines using a food-grade descaling solution, especially in areas with hard water.

Remove and soak removable parts such as drip trays, flavor holders, and pressure caps.

If your soda system allows it, flush the CO2 lines to ensure there’s no flavor residue or microbial growth inside.

Dry all parts thoroughly before reassembling the machine.

Remember to always unplug the unit and depressurize it before performing internal cleaning.

CO2 Cylinder Maintenance and Replacement

The CO2 cylinder is the heart of your carbonated soda machine. To keep the fizz flowing smoothly:

Store CO2 cylinders upright in a cool, dry location, away from direct sunlight or heat sources.

Check for leaks at the valve or regulator connection points using soapy water—bubbles indicate a gas leak.

Replace the cylinder before it runs completely empty. Some machines have pressure indicators; otherwise, you’ll notice reduced carbonation.

Inspect O-rings and seals regularly for wear. Replacing worn parts early prevents pressure loss and keeps the carbonation consistent.

Storage and Long-Term Care Tips

If you won’t be using your soda machine for several weeks or longer:

Turn off the machine and disconnect the power source.

Depressurize the system by removing the CO2 cartridge or cylinder.

Clean and dry all components, especially nozzles, tubes, and flavor chambers.

Cover the machine with a dust-proof cloth or storage case to prevent dust, insects, and moisture from causing damage.

Long-term storage without proper preparation can lead to mold, corrosion, or CO2 contamination. These issues are avoidable with a few simple steps.

Common Mistakes to Avoid

To ensure long-lasting performance of your soda machine, avoid these maintenance pitfalls:

Using harsh chemicals like bleach or vinegar can damage internal components or leave strong residues that affect taste.

Ignoring unusual noises, pressure drops, or leaks can lead to larger mechanical failures or unsafe pressure buildup.

Over-tightening CO2 connections may damage valves or seals, leading to unnecessary gas loss.

Always follow the manufacturer’s cleaning and maintenance recommendations, and use only food-safe materials.

Conclusion — Make the Fizz Last

A carbonated soda machine is an investment in convenience and sustainability—but like any appliance, it needs regular care. From simple daily wipe-downs to monthly deep cleans and proper CO2 cylinder handling, your efforts will directly impact the machine’s performance and the quality of every fizzy drink you enjoy.

Keep your soda dispenser running efficiently, and it will reward you with consistent carbonation, great-tasting drinks, and longer service life. Maintenance isn’t just a chore—it’s the key to preserving the bubbles you love.

FAQ

Q1: How often should I descale my soda machine?

A: At least once a month, or more frequently if you live in a hard water area or use the machine daily.

Q2: Can I use vinegar to clean my soda machine?

A: No. Vinegar can corrode internal parts and leave a lingering smell. Always use food-safe descaling agents.

Q3: How do I know when my CO2 tank is running low?

A: You may notice weaker carbonation. Some machines have pressure gauges, while others rely on performance drop as an indicator.

Q4: Is it safe to leave the CO2 cylinder connected when not in use?

A: For short-term breaks, yes. But for long-term storage, it’s best to disconnect and store the cylinder separately.

Innovative Features of Modern

Innovative Features of Modern

The Science Behind Carbonated

The Science Behind Carbonated

How to Care for Carbonated Sod

How to Care for Carbonated Sod

The Evolution of Carbonated So

The Evolution of Carbonated So