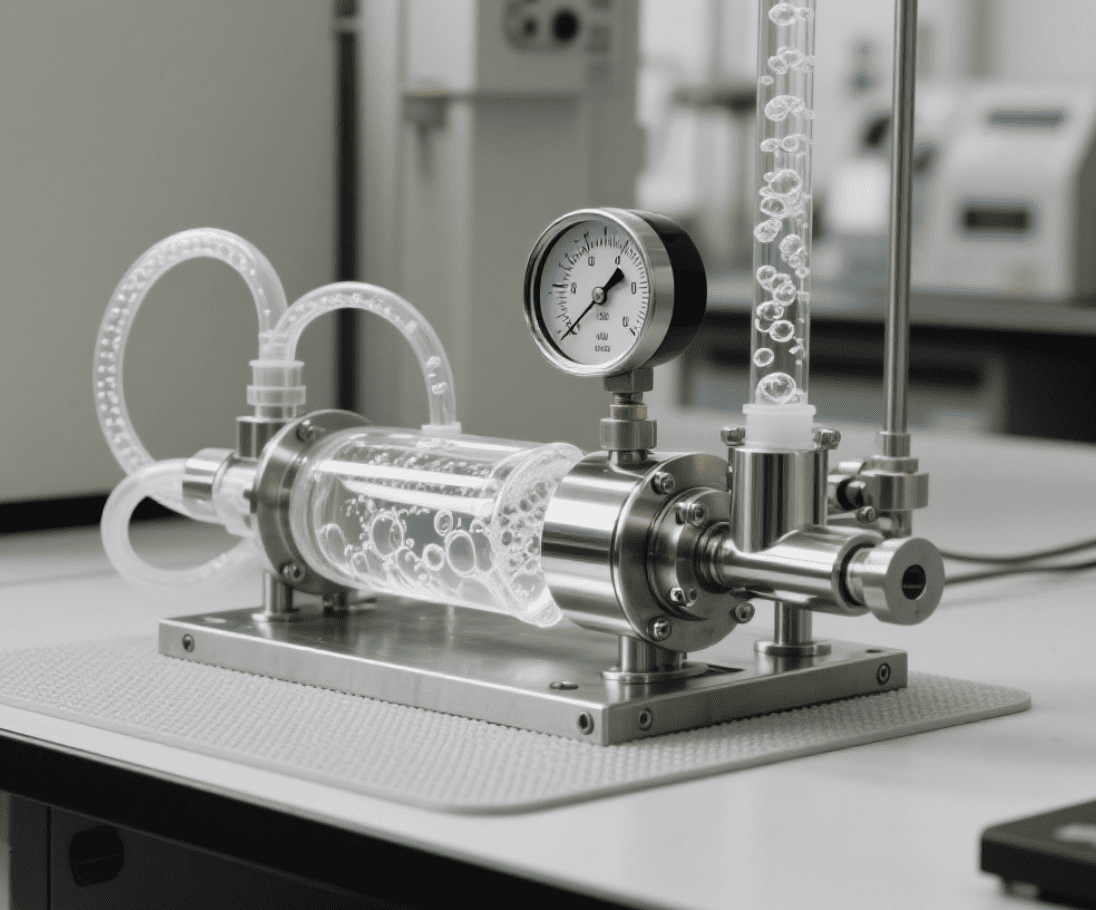

Choosing the right welding gas for your project

Welding is more than just fusing metals—it's a precision process where the right tools, settings, and materials directly influence the outcome. One of the most critical, yet often underestimated, factors in welding is the type of gas used. The right welding gas doesn’t just hold the arc or protect the weld—it determines strength, quality, and safety.

Whether you’re working with mild steel, stainless steel, or aluminum, the welding gas you choose must align with your material, technique, and performance expectations. This guide explores how to choose the right welding gas based on key project variables, gas properties, and safety considerations.

Why Welding Gas Selection Is Crucial

The gas you use in a welding process serves several essential purposes:

Shielding the weld area from atmospheric contaminants like oxygen and nitrogen, which can cause oxidation, porosity, and weak welds.

Stabilizing the arc and influencing arc characteristics, including shape, penetration, and heat distribution.

Affecting the appearance and durability of the finished weld.

Using the wrong gas can lead to excessive spatter, poor fusion, or metallurgical defects. In contrast, the correct choice enhances productivity, reduces rework, and supports workplace safety.

A Breakdown of Common Welding Gases

Understanding the characteristics and best-use cases of each gas helps narrow your options:

1. Argon (Ar)

A noble gas and the most widely used shielding gas for TIG and MIG welding, argon is inert, meaning it does not react with other elements during the welding process.

Best used for: Aluminum, magnesium, titanium, and other non-ferrous metals

Benefits: Clean welds, excellent arc stability, reduced spatter

Limitation: Low penetration when used alone for thick materials

2. Carbon Dioxide (CO₂)

Pure CO₂ is a common shielding gas in MIG welding, especially for carbon steel.

Best used for: Mild steel fabrication, especially when budget is a concern

Benefits: Deep weld penetration, low cost

Limitation: Higher spatter, less stable arc than argon blends

3. Oxygen (O₂)

Though reactive, small quantities of oxygen (typically 1–5%) are added to gas mixes.

Best used for: Carbon and stainless steel with MIG processes

Benefits: Increases arc stability, improves wetting and penetration

Limitation: Can oxidize weld metal and affect corrosion resistance

4. Helium (He)

Helium is an inert gas that creates a hotter arc than argon, making it suitable for thick materials.

Best used for: Stainless steel, aluminum, and copper alloys

Benefits: High heat input, deeper penetration

Limitation: High cost and low density, requiring higher flow rates

5. Gas Mixtures

Many commercial operations use blended gases to achieve a balance between performance and cost. Common mixes include:

Argon/CO₂ (75/25 or 80/20) – for improved arc stability in MIG

Argon/Helium – for deeper penetration and heat

Argon/Oxygen – for enhanced wetting and bead appearance

Using pre-mixed gases allows welders to benefit from multiple gas properties without manually adjusting the blend.

How to Choose the Right Welding Gas for Your Needs

Selecting the best gas depends on several factors. Let’s break them down:

1. Base Material Type and Thickness

Different metals react differently to shielding gases.

Aluminum and magnesium: Require argon for a clean weld

Mild steel: CO₂ or an Argon/CO₂ mix is standard

Stainless steel: Argon blends with helium or oxygen for strength and appearance

Thicker metals may need helium for additional heat and penetration.

2. Welding Process

The gas must complement your process.

TIG welding: Requires 100% argon (or argon/helium blends)

MIG welding: More flexible, often using argon/CO₂ or CO₂ alone

Flux-cored arc welding (FCAW): May not require shielding gas at all, depending on the wire

3. Desired Weld Quality and Appearance

If visual finish and minimal spatter are priorities, consider argon-based mixes. For deeper penetration and less concern about bead appearance, CO₂ might suffice.

4. Budget Considerations

CO₂ is economical but may increase post-weld cleaning

Helium and blended gases cost more but improve weld quality and reduce time spent on corrections

Striking a balance between gas cost and project efficiency is key for both small businesses and high-volume production teams.Learn more about our refillable CO₂ cartridges designed for cost-effective welding.

Storage and Safety Tips for Welding Gases

1. Safe Handling of Cylinders

Always keep gas cylinders upright and secure them to prevent tipping.

Store in a cool, dry, and well-ventilated area, away from flammable substances.

Label all cylinders clearly with contents and pressure levels.

2. Leak Detection and Ventilation

Inspect all hoses, regulators, and valves regularly.

Use soapy water to detect leaks at connections, or use certified gas detectors.

Ensure proper room ventilation, especially when working in enclosed spaces.

Following these best practices prevents injury, fire hazards, and gas-related contamination.

Conclusion: Making an Informed Choice

The choice of welding gas may not be as visible as your welds, but its impact runs deep. Whether you're fabricating steel frames, working on aluminum components, or fine-tuning precision welds, selecting the correct shielding gas is crucial to success.

To make an informed decision:

Match the gas to your material and process

Balance quality with cost-efficiency

Prioritize safety in storage and usage

Need help choosing? Browse our collection of CO₂ cylinders or contact us for expert guidance on selecting the best welding gas for your application.

FAQ: Choosing Welding Gases

Q1: What’s the difference between pure CO₂ and Argon/CO₂ mix?

A: Pure CO₂ offers deeper penetration and lower cost, while Argon/CO₂ blends reduce spatter and improve arc control.

Q2: Is helium worth the cost in welding?

A: Yes, especially for thick materials and non-ferrous metals where deeper penetration and higher heat are needed.

Q3: Can I use the same gas for MIG and TIG?

A: No. TIG usually requires 100% argon, while MIG may use various mixes based on the metal type and desired weld quality.

Q4: How should I store unused gas cylinders?

A: Store them upright, secured, and away from heat or ignition sources. Label them clearly and keep them ventilated.

Q5: What if I choose the wrong gas?

A: You may experience poor weld quality, increased defects, and safety issues. Always match the gas to your project type.

Innovative Features of Modern

Innovative Features of Modern

The Science Behind Carbonated

The Science Behind Carbonated

How to Care for Carbonated Sod

How to Care for Carbonated Sod

The Evolution of Carbonated So

The Evolution of Carbonated So