The Role of Welding Gases in Metalworking

In the world of metalworking, welding gases play a vital role in determining the quality, strength, and appearance of a weld. Whether you’re working with carbon steel, stainless steel, or aluminum, choosing the right welding gas is essential. These gases are more than just passive elements—they actively shape how the arc behaves, how deep the penetration is, and how clean the final weld appears.

In this guide, we’ll explore the types of welding gases, their properties, and how they contribute to successful metalworking processes.

Introduction to Welding Gases in Metalworking

Why Shielding Gases Matter in Welding

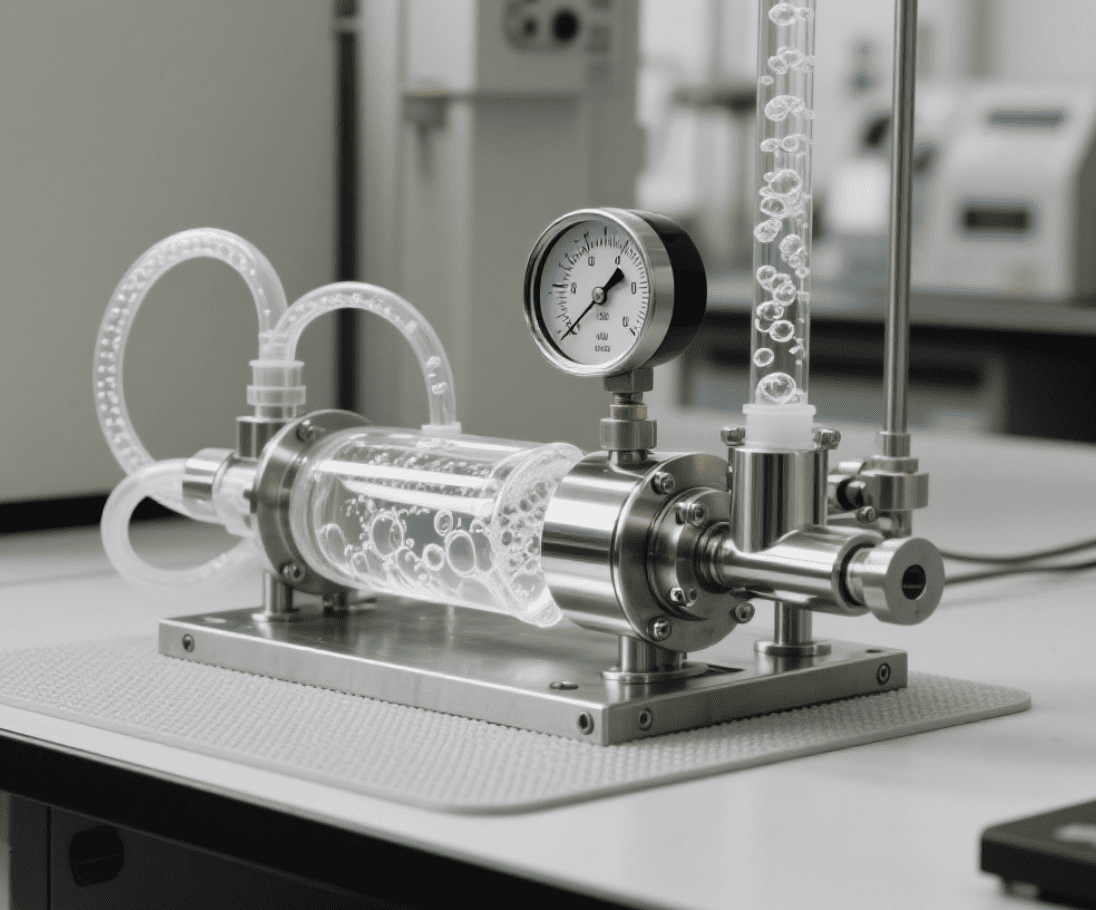

Welding gases, especially shielding gases, are essential in arc welding processes. Their main role is to protect the molten weld pool from atmospheric contamination, including oxygen, nitrogen, and water vapor. If unprotected, these elements can cause weld defects such as porosity, spatter, or brittleness.

The Link Between Gas Selection and Weld Quality

The type of shielding gas you use impacts:

Arc stability

Penetration depth

Spatter generation

Weld bead appearance

Cooling rate

Selecting the right gas ensures cleaner welds, better fusion, and fewer post-weld corrections.

Common Welding Gases and Their Properties

Argon – The Universal Shield

Argon is an inert gas and the most widely used shielding gas in TIG (GTAW) and MIG (GMAW) welding. It provides excellent arc stability and prevents oxidation. Pure argon is typically used for non-ferrous metals like aluminum, while mixtures are used for steel.

Carbon Dioxide (CO₂) – Budget-Friendly Option

CO₂ is a reactive gas, commonly used in MIG welding of mild steel. It provides deep penetration but produces more spatter and a less stable arc compared to argon. However, it’s cost-effective and widely available.

Helium – High Heat for Deep Penetration

Helium is another inert gas that creates a hotter arc than argon, offering deeper penetration and faster welding speeds. It's ideal for thick materials and aluminum but is more expensive than argon.

Oxygen – Enhancing Arc Characteristics

A small percentage of oxygen (1–5%) is often added to shielding gas mixtures. It improves arc stability, weld pool fluidity, and mechanical properties. However, too much oxygen can oxidize the weld and base metal.

Gas Mixtures – Optimizing Performance

Many welding setups use mixed gases to balance penetration, spatter control, and arc stability. Common blends include Argon/CO₂, Argon/O₂, or Argon/Helium. These combinations are tailored to specific welding applications and base metals.

Application of Gases in Different Welding Methods

TIG Welding (Gas Tungsten Arc Welding)

TIG welding requires high-purity shielding gases like argon or argon-helium mixes. The gas stabilizes the arc and ensures a clean, spatter-free weld—ideal for precision applications like aerospace or piping.

MIG/MAG Welding (Gas Metal Arc Welding)

MIG (using inert gases) and MAG (using active gases like CO₂) rely on gases to regulate penetration and bead shape. For example:

Argon-rich mixes: smooth arc, low spatter

CO₂: strong penetration, rougher finish

Tri-mix (Argon/CO₂/O₂): optimized for stainless steel

Flux-Cored Arc Welding (FCAW)

In gas-shielded FCAW, external shielding gases like CO₂ or Argon/CO₂ mixes are required. The combination of flux core and shielding gas provides good coverage and deep weld penetration.

Selecting the Right Gas for Your Metal Type

Steel

Mild steel welding works well with 100% CO₂ or Argon/CO₂ mixes. For smoother finishes and less cleanup, argon-dominant blends are preferred.

Stainless Steel

Use a tri-mix of Argon, CO₂, and O₂, or Argon/Helium/Nitrogen depending on thickness and position. These prevent oxidation and improve arc performance.

Aluminum

Always use pure Argon or an Argon/Helium mix for aluminum welding. Helium enhances heat input, making it easier to weld thicker aluminum sections.

Safety and Storage Tips for Welding Gases

Store cylinders upright, secured, and in well-ventilated areas

Use proper regulators for each gas type

Check for leaks using soapy water, not open flame

Keep away from heat or direct sunlight

Never mix gases unless using certified pre-mixed solutions

Safety should always come first, as pressurized cylinders and flammable gases pose serious risks if mishandled.Explore our CO₂ welding gas product catalog

FAQ: Choosing and Using Welding Gases Wisely

Q1: Can I use the same gas for all types of welding?

A: Not recommended. Different metals and welding methods require specific gases for optimal results.

Q2: What’s the best gas for aluminum welding?

A: Pure Argon is preferred, with Helium added for thicker materials.

Q3: Are gas mixtures better than pure gases?

A: Often yes. Gas mixtures combine the strengths of different gases, improving weld quality and efficiency.

Q4: Is CO₂ suitable for TIG welding?

A: No. CO₂ is a reactive gas and not suitable for TIG, which requires inert gases like Argon.

Q5: How should I store welding gas cylinders?

A: Always upright, in cool, ventilated spaces, away from heat sources and potential impact zones.

Innovative Features of Modern

Innovative Features of Modern

The Science Behind Carbonated

The Science Behind Carbonated

How to Care for Carbonated Sod

How to Care for Carbonated Sod

The Evolution of Carbonated So

The Evolution of Carbonated So